Most orders for IN STOCK items placed by 12PM CST M-F ship SAME DAY. Orders for custom items and prints may take additional time to process.

Stepper motors are used in so many things you buy today and most people don’t even know it! They truly are amazing little pieces of electronics and mechanics combined into one. Even the vibrator built into your phone is likely based on stepper motor technology! In this tutorial we’re going to cover the basics of how stepper motors work. We think you’ll find it super interesting.

Let’s start with the very basics of how a stepper motor actually works. The fundamental basics behind them are all about magnets! Who doesn’t love magnets?

Let’s start with the very basics of how a stepper motor actually works. The fundamental basics behind them are all about magnets! Who doesn’t love magnets?

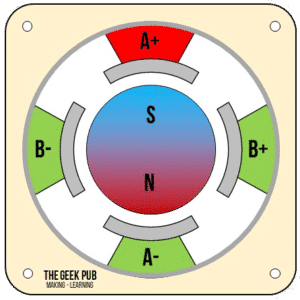

Looking at the picture on the right you’ll see our cross section of a stepper motor. In the center is a round shaft connected to a permanent magnet, seen here as N/S (north and south poles). We call this the rotor. It’s the part that spins when the stepper motor is in action.

Surrounding the rotor is a set of windings containing coils. These coils of the stator become magnetized or demagnetized when we add to or remove current from them. The stator here is represented as A+, B+, A-, and B-.

The magnetic fields created around the stator interact with the North and South poles of the rotor’s permanent magnet. As you can see in the diagram below, these interactions cause the rotor to turn and align to the section of the stator it is attracted to. In a nutshell, that’s how stepper motors work. But let’s dive deeper!

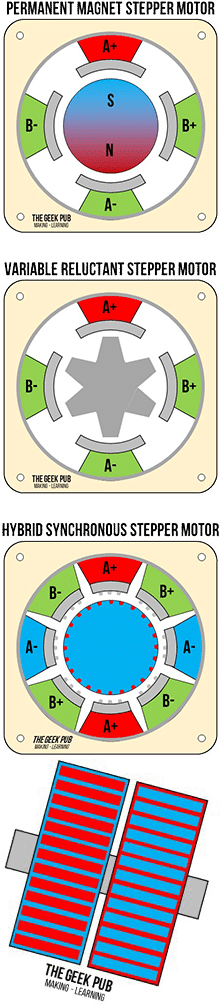

A permanent magnet stepper motors work pretty much how they sound. They have a permanent magnet rotor in the center that is driven by the electromagnets of the stator windings. The stator delivers a polarity that is opposite of one of the rotor’s poles and therefore attracts that pole and it rotates towards it. Permanent magnet stepper motors work well in low speed applications where relatively high torque is required.

A variable reluctant stepper motor works unlike the other types, and rather uses a non-magnetized rotor. This type of stepper motor is the simplest design. The rotor is generally made from iron and has teeth that are offset from the stator. When the windings are magnetized the rotor will align itself where there is a minimum gap between itself and the stator. Variable reluctance stepper motors often used for high speed applications, where accuracy is not as important. This design is also considered to be the noisiest type of stepper motor.

Hybrid synchronous stepper motors work exactly as you’d suspect. They are a hybrid design that includes concepts from both permanent magnet design and variable reluctance design! In this design, the stepper motor has two cups on the rotor. Each cup is lined with many permanent magnet “teeth”. The stator itself is also toothed. This gives hybrid designs a best of both worlds performance. It has high torque, can operate at higher speeds, and is very accurate. In addition, the toothed design gives the hybrid synchronous stepper a high resolution with models having 500 or more steps per revolution!

Now let’s learn about how motors are actually driven.

As we continue to learn how stepper motors work, let’s dive into the four different drive modes: wave drive, full step, half step, and microstepping. Since the entire principle of stepper motors is based on the energizing and de-energizing of electromagnets, a circuit must know how to pulse or hold these magnets in order for the stator to cause the rotor to move in the right direction, and to the right position.

The first type of drive mode is called Wave Drive (or sometimes engineers like to say “single coil excitation”). In this drive mode only a single coil on the stator is ever active at once. In our example below, there are four coils. With wave drive this results in four total positions.

Full step drive is similar to wave drive, except that at any time two coils are magnetized. This type of drive is common when more torque is needed for the same number of positions. It’s the same basic operating principle behind wave drive, but with roughly double the torque and double the power requirements.

With half step drive, it takes wave and full step and combines them together! Step one activates a single coils, step 2 is half step and actives two coils. Step 3 would then active only the third coil. We lose the increased torque of full step on half of the positions, but we double the number of positions! In this case, we have four coils on the stator, but 8 total positions.

Microstepping is the most complicated form of stepper motor drive and is what most modern devices use (of course!). Microstepping uses pulse width modulation (PWM) to provide a variable current with microstepping a four coil stepper motor could have 20 positions! We have a tutorial on it if you’re interested in learning more about PWM.

Let us know in the comments if you have any questions or how we can improve this tutorial!

If you like our content maybe consider upgrading to Premium. You’ll get access to

2 Responses

5

Leave a comment here if you need help with stepper motors! We’ll do our best to help!