Blog

Grounding a Dust Collection System

[adinserter name=”TopOfPost”]In a recent article and video publication we discussed installing an Automated Dust Collection System. In this article and video we installed a PVC “grounded” dust collection system into the shop. PVC is very prone to generating a static charge when air is moving along the inside of it, along with charged particles of wood and other debris. Think about combing your hair with a plastic brush. The same thing is happening in your dust collection system, on a much larger scale. This static can build up to the point where it arcs to ground unexpectedly. With the right combination of materials and and oxygen levels, this can cause a dust fire or an explosion to occur. Not something you want in your shop!

During the course of the article and video we talked about the importance of grounding, and how the grounding system for PVC works. However, we didn’t really go into the grounding of the system to an actual ground source. That’s what we’re going to discuss today.

Grounding Dust Collection

Let’s recap the basics of installing and grounding dust collection before we go on. It’s a good recap, especially if you’ve not yet seen the video on installing the PVC grounded dust collection system at The Geek Pub shop. The basic premise of grounding the system is to keep the air and PVC in constant contact with a ground. There are numerous ways to do this. In fact, if you were to choose a dust collection ducting of the metal variety (such as tin, steel, or aluminum), then grounding would already be inherent in the system simply by its basic composition as long as something is connected to the system that bridges it to ground, such as being connected to the dust collector at one end, or a metal table saw at the other end.

Grounding of insulated material such as glass, plastic, or PVC is accomplished by wrapping the pipe with a braided copper wire and attaching it an various points. Many recommend running the wire on the inside of the pipe, or both wrapping the pipe and including a conductor in the center.

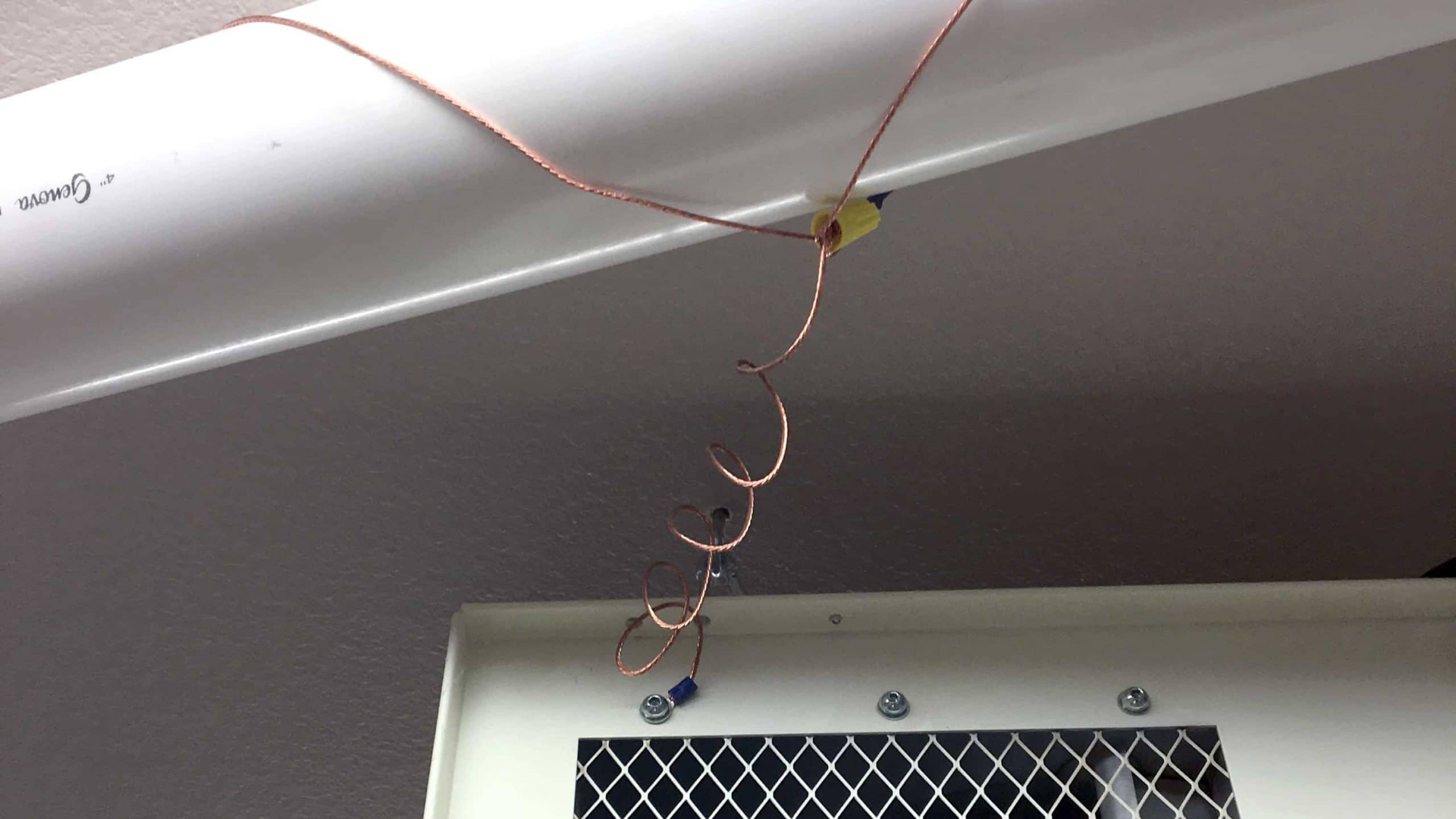

In The Geek Pub dust collection system, we wrapped the PVC pipe with braided copper ground wire kit. At approximately every 48 inches the wire was terminated to a grounding lug via a 3/4 inch screw that penetrated to the interior of the PVC pipe. In addition, blast gates are grounded by connecting a grounding lug to one the gates screws, or a dedicated grounding terminal if one is provided on the blast gate. This provides a grounding mechanism for both the inside and outside air.

Connecting the Dust Collection System to Physical Ground

The most common piece of feedback or line of questioning I got on the previous article was around actual connection of the system to a physical source of grounding. This is something that wasn’t covered in the video or article, but of course the best grounding solution in the world is of no value if it isn’t actually connected to ground!

Grounding your dust collection is easy. In The Geek Pub shop, I elected to connect my grounding system to physical ground at numerous locations:

- To the physical metal from of the dust collector itself. My dust collectors frame (as all should be) is connected to the same ground as the A/C outlet and the machine’s motor. There is a screw on the inlet pipe that is the perfect place to attach to.

- To the metal from of the permanently connected tools. Each tool has a grounding lug on it, and should be connected to the grounding system of the dust collection system.

- To my Jet Air Filtration unit on the ceiling. This grounds the system at the center point. This doesn’t make the ground “better”, rather just increases redundancy.

- To a wall outlet. I purchased a three-prong plug at the local home improvement center and connected the grounding system directly to the ground lug (leaving the other conductors un-touched and insulated).

Grounding Dust Collection is Important

Grounding dust collection is very important. I’ve stressed this numerous times. There are many grounding deniers out there. Don’t be one of them. A shop fire or PVC explosion is a very dangerous situation that will most likely result in loss of property and possibly life. Grounding your dust collection system is easy and quick, and pretty inexpensive. Don’t skip such an important step in your workshop!

Head over to Amazon and get your dust collection grounding kit.

Leave your Grounding Ideas in the Comments below!

If you have any additional ideas or experience on grounding dust collection systems, please leave it in the comments below so we can all learn!

I really like what you said on Reddit about about this. You’re right. There’s a 99.9% chance there will never be a dust fire in your shop. But for how cheap and affordable it is to install, who want to risk being the one dude it does happen to?

And if that’s not a enough, a lot of cities require you to ground PVC ducting to pass inspections. California doesn’t even allow PVC. It’s banned statewide. You must used metal ducting!

Good point! It is required by code in my city as well.

If you ground your system and your duct runs between the floor joist can you still insulate around the pipe?

I’ll tell you why a grounded my system! I grounded it because I got tired of getting my drawers shocked off every time I touched the damn thing! That static freakin hurts like a biotch!

Funny you say that. My DeWalt DW735 planer is like the static electricity king! I can always feel the static the closer I get to it and then zap! It shocks me as I touch the outfeed table.

It’s funny you mention that, I was looking up a way to ground my dust collection system (nothing fancy one of the 5 gallon buckets with a special lid attached to a shop vac) and came across this article and comment. I got blasted taking the lid off of the bucket yesterday while using it with….

A DW735 planer.

I assume I can ground the tubes and bucket in a similar fashion? Hardest I’ve ever been shocked in my life so I don’t want to repeat it!

Yes! You can just ground the tubes the same way you’d ground a dust collection system.

Thanks for your input on grounding the dust collection system. I’ve been doing a lot of searching for how to do mine, as I get ready to build it. I think people are stupid for not grounding it. I do have a question for you. My system is going to be run mostly of clear flex tubing with PVC fittings. My collector is a metal trash can sitting on the concrete floor. Should I ground it off to something else? Or will it work as its own ground. I do have the main home water line I could ground it to but nothing else near by, being an unfinished basement.

If your metal trash can doesn’t have a low-resistance path to actual earth ground, it won’t work. Easiest is to get a 3-prong AC plug and connect a wire to only the ground lead, and plug it into a grounded AC outlet. Static has very low current so you don’t need a big heavy wire.

My system is run off a Shop Vac also

Mike,

I have a small shop and have built a dust separator out of a plastic trash can and lid. I don’t have stationary pipes for dust collection, but I think it would be good to add a grounding wire to the trash can. I’m thinking of running a coil of wire inside the trash can (wrapping it around some screws to secure it). To make the can portable I was going to attach both ends to the same ground screw (green screw) in a plug alone and plug into the wall. Do you see any issues with that or should I attach one end to the DC and the other end to a plug?

I love the dust collector explosion deniers… because of the 99.9% argument. The problem is, the conditions for explosion don’t occur very often but when they do… boy can it be devastating.

I used to work at a major food manufacturing plant. (I’ll withhold the name since I’m not an official of theirs anymore but you can look it up by date if you’re interested… Dec. 11, 1916) In their history, they had an explosion that occurred because of a perfect combination of flour dust, humidity level and oxygen in the air. Not only was the building partially demolished but 24 employees lost their lives… 24 people died!

in looking up grounding for dust collector systems I happened to see a few comments by pretty knowledgeable people, who used the argument that they had never heard of any explosion or fire actually occurring from lack of grounding. Well you know what… back a few hundred years ago, people believed there was no possibility in the world that man could travel at speeds greater than 40 km/hr… because they had never seen or heard of such a concept. Newton was laughed at when he made that claim. Just because one hasn’t heard of dust collection explosions makes for a pretty foolish approach to such an important consideration. Fools.

I don’t want to mess around with 99.9% safety measures when that .01% has the potential of death involved. Bottom line… yes there is a very small remote chance that one day I might be creating an excessive amount of dust for some bizarre job, and that day might have exactly the right humidity levels and oxygenation in the air… yes it’s possible. So I’m not going to neglect such an easy safety step of grounding my dust collection system when that possibility carries with it the potential for so much devastation.

Or think of it this way… knowing parachutes rarely fail but still have backup secondary parachutes… would you jump out of a plane using a parachute that didn’t have a backup?

I have been in the industrial wood production business my whole life – I have had an entire plant go up in smoke from sparks from un-grounded dust systems (Dry shavings plant for horse bedding). The setup above IS NOT SAFE – static electricity within a dust collection system can generate substantial DC voltage. You cannot, and should not EVER ground DC voltage into an AC ground. It puts any branch circuits that are close by at risk of overheating. DC grounding must be done on its own ground rod, or some other earth ground. Electricity DOES NOT and I repeat DOES NOT go back to ground – it goes back to the source. You will likely make any hazard you were trying to fix – even worse if you do it like above.

Dude. You need an education. There is only one ground in the entire world. The ground you are walking on. This is why sometimes grounds are also referred to as Earth. All grounds go to the same place. AC or DC is 100% irrelevant. They all go to the same place. Stop spreading bullshit.

Bryan… https://i.imgur.com/qGhiEIe.gif

5

The purpose of grounding the chassis of electrical machinery is to make sure that any accidental connection with the powered wire has a much better path to ground (the chassis) than your body. To be a better path to ground it has to be very low resistance (maybe one ohm). This helps protect your body from high current. The purpose of grounding dust collector tubing is different. It prevents a build up of charge that can lead to a spark and then an explosion. This path can be much higher resistance and work fine. It just needs to be lower resistance than a jump through the air. If you connect dust collector tubing to AC electrical ground through a 10K ohm resistor or larger you can provide a great path to ground for static build up without adding any risk of unexpected high current flow.

My name is Ed H. When I built my shop I put 3″ PVC pipe in the ground and covered it with concrete. Does this serve as a sufficient ground? Please let me know.

Thank you

PVC is an excellent insulator. IOW, no, it won’t work.

1

You might also want to consider putting a 1m-ohm resistor between the ground conductor coming from your dust collection lines and the ground lug in the plug you use. This will prevent you or someone else from getting a potentially serious shock if any of the other equipment that is plugged into the same outlet gang box that might have a ground malfunction. Keep in mind you are only trying to drain off the built up static charge. There’s no need for immediate discharge. The resistor will prevent any current that might be on the ground line from a potentially malfunctioning peice of equipment from traveling up the dust collection discharge line to you.

It’s actually never happened in a home shop, your dust collection system can not suspend enough fine wood dust in the right volume of air to create this situation. It only happens in industrial production environments. People sometimes have a fire because one of their tools sucks up a smoldering ember from a blade hitting a nail or something but there is not 1 single confirmed case of an explosion in a home shop because of wood flour in the air. it’s not 99.9% it 99.99999%

Grounding your system by wrapping the copper ON THE OUTSIDE of the PVC is completely useless. PVC is an insulator and therefore, grounding the outside in the hopes of preventing electrical buildup simply will not work. You can test this yourself by rubbing the outside of the tube with a microfibre cloth and then testing the charge on the inside of the tube with a multimeter, then testing it on the outside. You will notice there’s no charge when you test the inside. If you’re going to ground it, you need to ground it on the inside of your tubing.

As mentioned in the video, the whole point is to run screws into the pipe that are grounded from the outside. The tips of the screws are similar in concept to a lightning rod. Putting the grounding cable inside the pipe is a recipe for disaster. The wire will cause air turbulence and catch particles causing buildup and eventually clogging the line.

A spark has set fires in wood shops where flammable fumes from finishing materials exist. My boss use to chew my ass for smoking in the finish room….