Most orders for IN STOCK items placed by 12PM CST M-F ship SAME DAY. Orders for custom items and prints may take additional time to process.

CNC stands for Computer Numerical Control. But that probably doesn’t help much either. If you’ve ever used a woodworking router you know it can cut and carve wood in numerous different ways. You can cut slots, dadoes, rabbets, etc. You can add decorative edges to wood. You can even use it to just drill simple holes using a guide. It wasn’t too long after routers hit the market that people realized you could make a template from thin wood and use that template to carve intricate designs into wood. You could cut out circles easily, or make a free-form bowl.

Beyond wood, the X-Carve is capable of cutting metals, plastics, and other materials. One of my first projects will actually be milling expanded PVC.

At first you might be thinking that I am not happy with the experience, but that’s not the case at all. The X-Carve is an open source machine based on off-the-shelf components. And it is advertised as such. Inventables is very clear with what they have designed and what you are buying. I’m telling you this because you need to be ready to spend hours (six or more) putting it together. The assembly itself is a project. Think of it like any other shop project you do. One of my friends compared it to hobby RC cars. You don’t buy the car, you buy the pieces, you build the car. The X-Carve is very much the same.

The X-Carve arrives in multiple boxes. In my case I received five boxes over several days consisting of 1) the wasteboard, 2) the maker slides, 3) the spindle, 4) some material and bits, and 5) the core components and electronics. There are no instructions in the box, only a packing list, and a sheet of paper with the URL of the online assembly and set-up instructions. I assembled mine reading the instructions my iPad (mainly because the battery lasts forever).

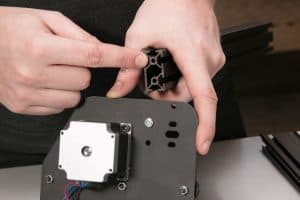

There’s a lot of detailed work and very small components to work with. Find yourself a large table to assemble this thing on. If you bought the limit switch option you’re going to also need to break out your soldering iron. I also broke out my helping hands with a magnifier installed to make sure I could see the tiny soldering locations on the gSheild and micro-switch leads.

Be prepared to make a few mistakes and have to take things apart. It is going to happen. Sometimes the instructions just aren’t clear, but sometimes you’ll just make a mistake. More than once I assembled ahead thinking I already knew the next step only to find out I was wrong.

If I had had time, I would have ordered a tap from Amazon with the correct thread pattern and tapped these holes the right way first. Too bad I didn’t know about this ahead of time. Since you’re probably already in the same boat there is one thing that will make a dramatic difference: WD40. Cover the threads of the screw with penetrating lubricant before running them in. This will cut your effort in half. Make no mistake, its still a huge pain. My advice to Inventables would be to either actually include thread cutting screws, or to tap these holes at the factory. Anyway, it does work as shipped, just not without making my wrist sore for two days.

This wraps up into a nice little package that simply sits next to the X-Carve. I did add rubber feet to the bottom of the power supply to help it stay still when the surface is vibrating.

Well that’s all for this update. More to come in next weeks blog post!

You can follow along with my X-Carve build (and other projects) on Facebook and Instagram. I post new pictures daily.

If you like our content maybe consider upgrading to Premium. You’ll get access to